|

|

Working principle

When the ball mill is in operation,the grinding media and materials in the horizontal cylindrical mill are raised to a certain height by the rotation of the cylindrical body, and then fall down along the parabolic trajectory due to gravity. The materials are ground by the impact of the grinding media, the friction and the shearing action generated by the rolling and sliding of the grinding media. |

Technical Parameters :

Ball Mill Jars: Single Jar: 5 L

Jar Materials: Alumina,

Jar Types: normal,

Max Feeding Capacity: 2/3 capacity of the grinding jar

Net Weight: 32kg

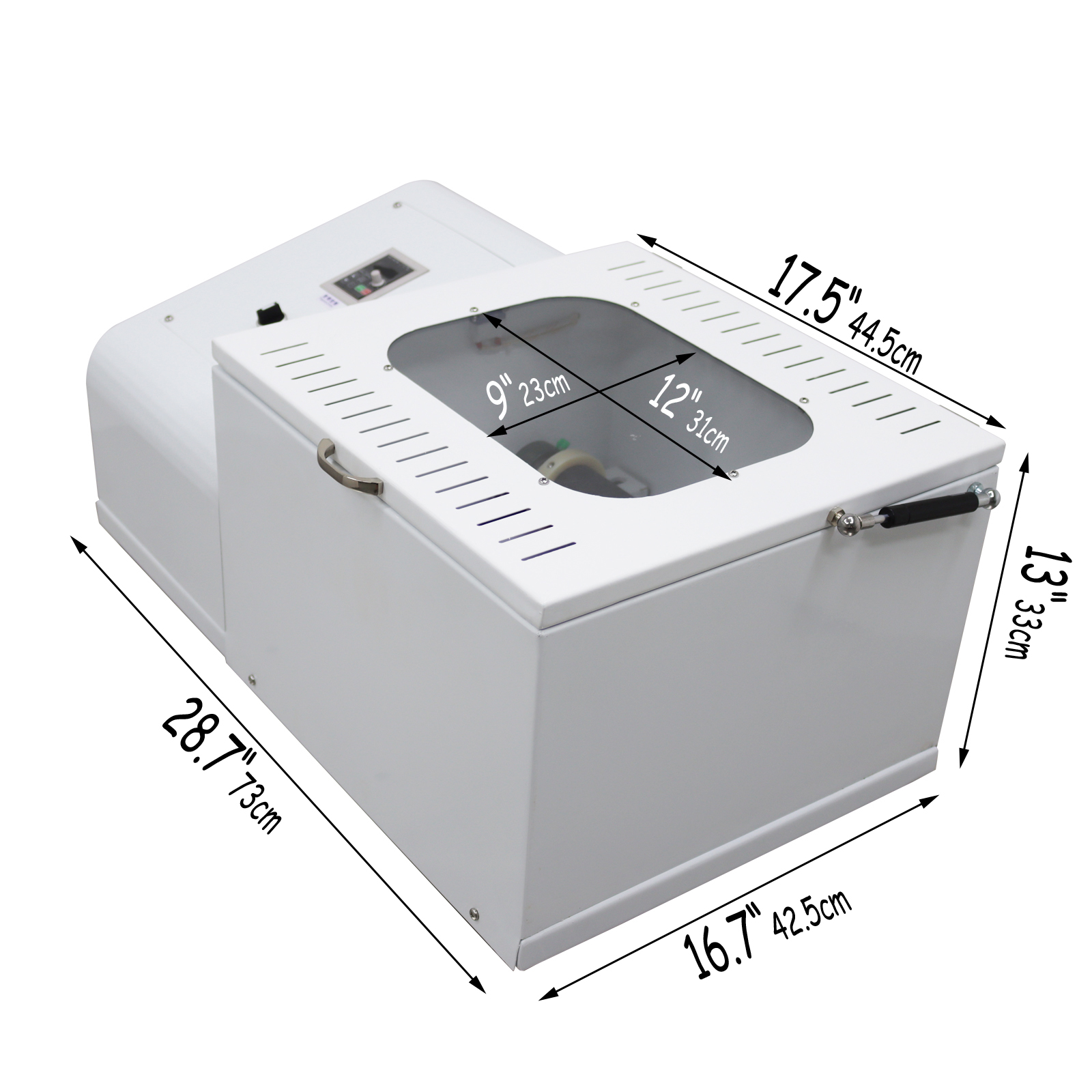

Product Dimension: 28.7*16.7*13inch(730*425*330mm

)

Electrical Details: Single-phase alternating voltage 220-240V ± 10% .

Maximum power consumption: About 250W

Switch on by pressing in the green button at the rear of the machine.

Sintered corundum(99.7% Al2O3): density 3.8 in g/cm3, resistance to abrasion,Fairly good.

Warning:

Read carefully and understand all INSTRUCTIONS before operating the machine. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury.

-Always keep children away from this machine, PROHIBIT children from operating the machine.

|

|

Heat dissipation

Ensure that there is good access to the instrument. There must be enough space to reach the main switch.

Do not block the air outlet in the ventilation louver on the side. There is a danger of over heating if the louver is blocked. |

| Rheostat variable speed control adopts precision pressure regulating knob for voltage regulation, with high accuracy and good stability,Through the digital display screen, you can accurately understand the working voltage of the machine. |

|

|

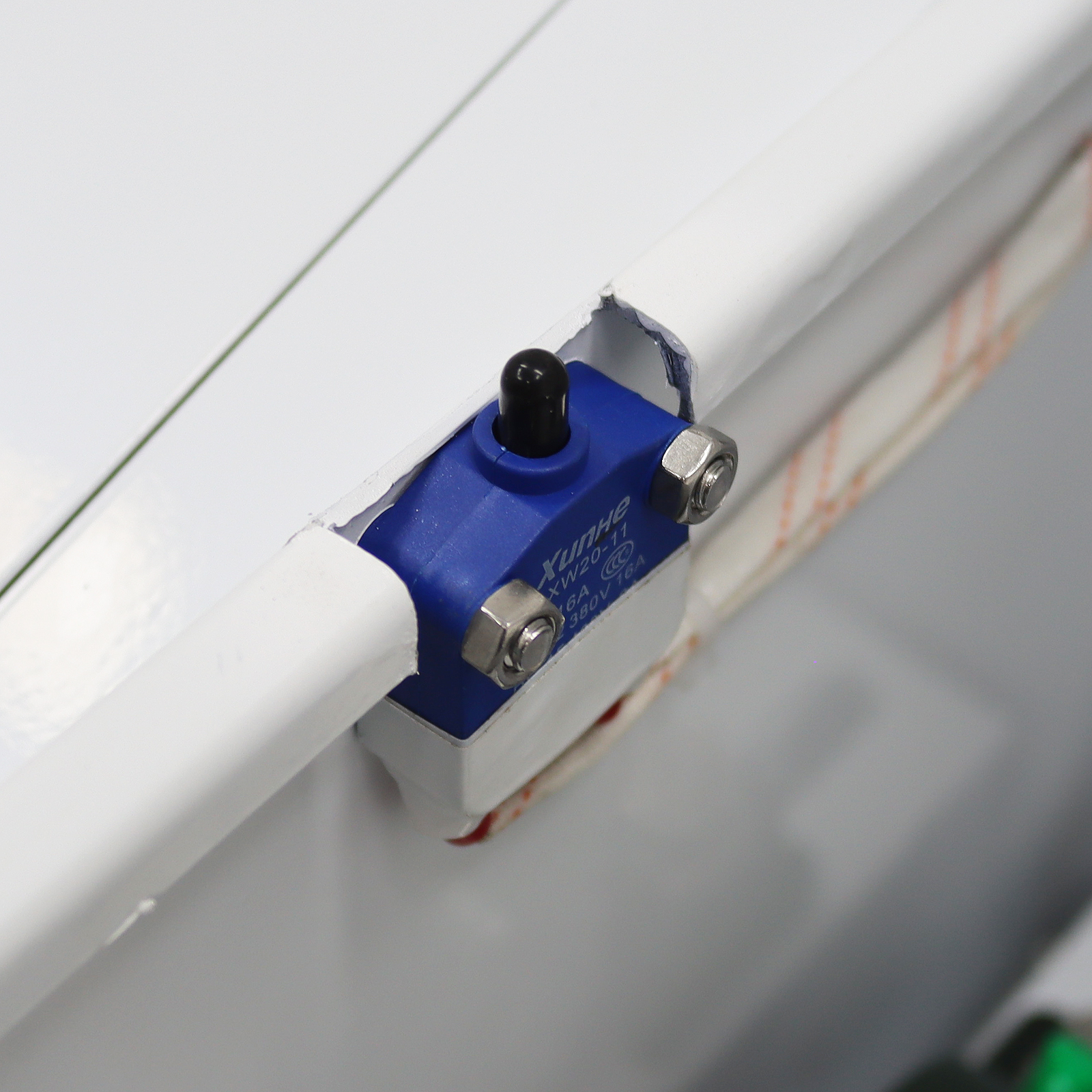

Switch for immediately stopping the machine when the lid is opened. |

| Window |

|

|

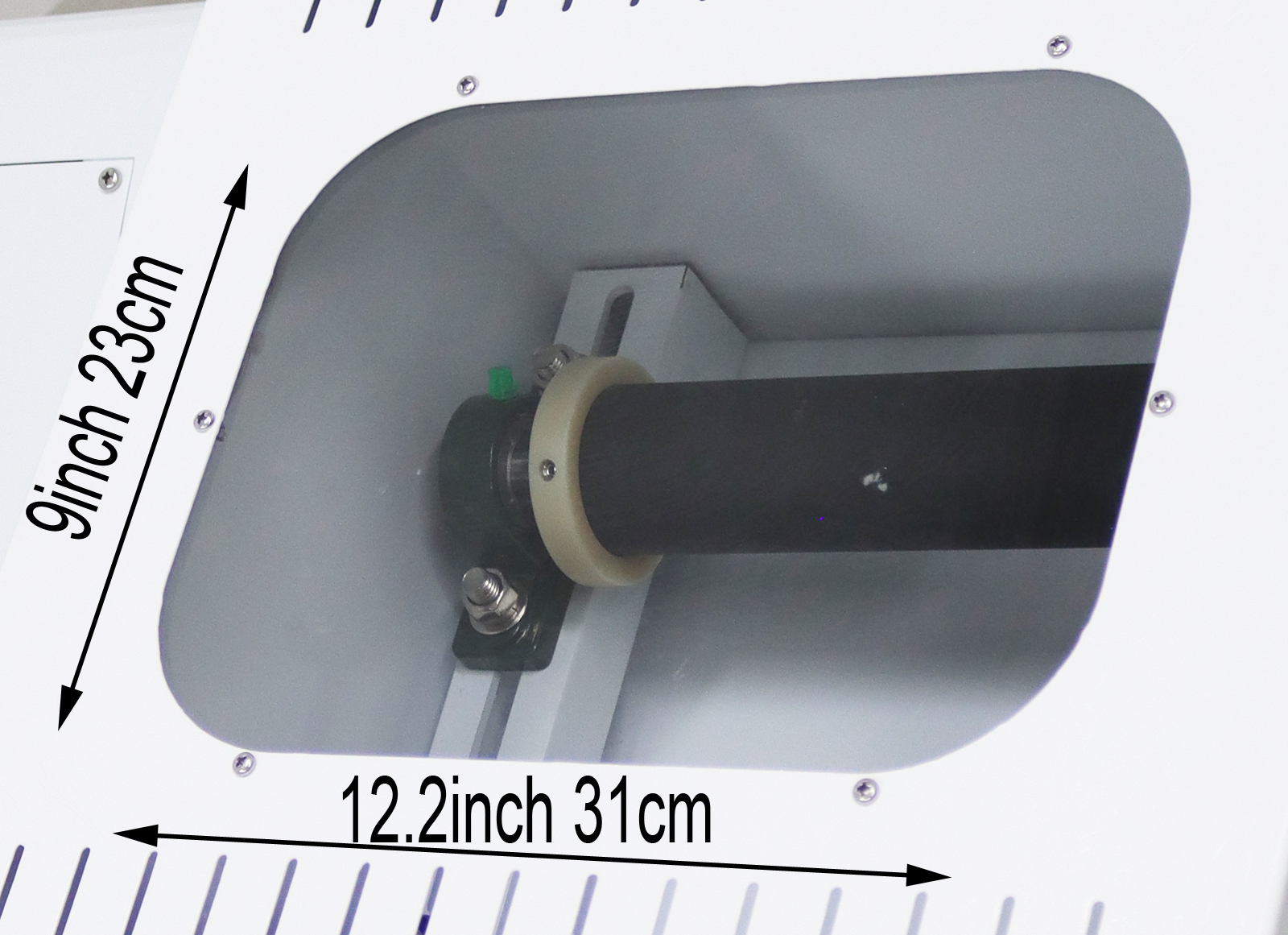

Roller

The width can be adjusted.

Adjustment range:50ML-5L |

| Alumina grinding balls,Three models (5/10/15mm) |

|

|

Alumina grinding tank(5L)

It is imperative that the following sequence be observed:

1.Place the grinding balls in the empty jar.

2. Fill the remaining space of the jar with the material to be ground.

-Never use the mill without sample material! Danger of serious damage of the grinding balls and jars!

-A longer grinding time will increase the fine fraction. To reduce the grinding time you can use grinding jars and balls with a higher density and therefore with a higher impact energy.

-A higher speed will reduce the grinding time and increase the fine fraction. |

How to use

Switching On:

-Connect the machine to the mains supply.

-Press RUN on the control panel.

-The mill will run at the preselected speed.

Switching Off

Press STOP on the control panel.

After a short period (after the mill has stopped), open the hood. |

|

Item# |

QTY |

| 134126 |

1 |

|

Item inclued:Horizontal Drum Small Laboratory Ball Mill 5L 220V 250W

Item Number: 134126 |

| You can make order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in normal condition.

Handling Time: Shipping is usually made in 1-3 business days after payments cleared. Orders are processed from Monday-Friday; Not on the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty period has expired, you can still seek for service or technical support from us with low cost. |