|

|

Automatic Paper Folding Machine 110V |

|

|

|

|

|

|

|

|

Product

Overview |

|

The automatic paper folding machine is a

small horizontal professional device for folding paper in different

styles. It is equipped with two folding trays, an automatic counter and

a speed regulator to fulfill the functions of automatic folding,

automatic counting and speed adjustment. Compared with manual folding

mode and semi-automatic folding machine, the automatic paper folding

machine has the advantages of greatly improving the working efficiency,

reducing the operating difficulty, saving time and labor, achieving

energy saving and environmental protection and having a perfect folding

effect. It can be widely applied to fold the product manuals, official

documents, letters, commercial cards and so on. |

|

Product

Parameters |

|

Power supply |

110V/60Hz |

|

Power |

70W |

|

Number of folding trays |

2 pcs |

|

Maximum paper size |

31*70cm (12*27

inches) |

|

Minimum paper size |

5*7cm (2*3 inches) |

|

Thickest paper specification |

125g |

|

Thinnest paper specification |

40g |

|

Maximum speed |

80m/min (262ft/min) |

|

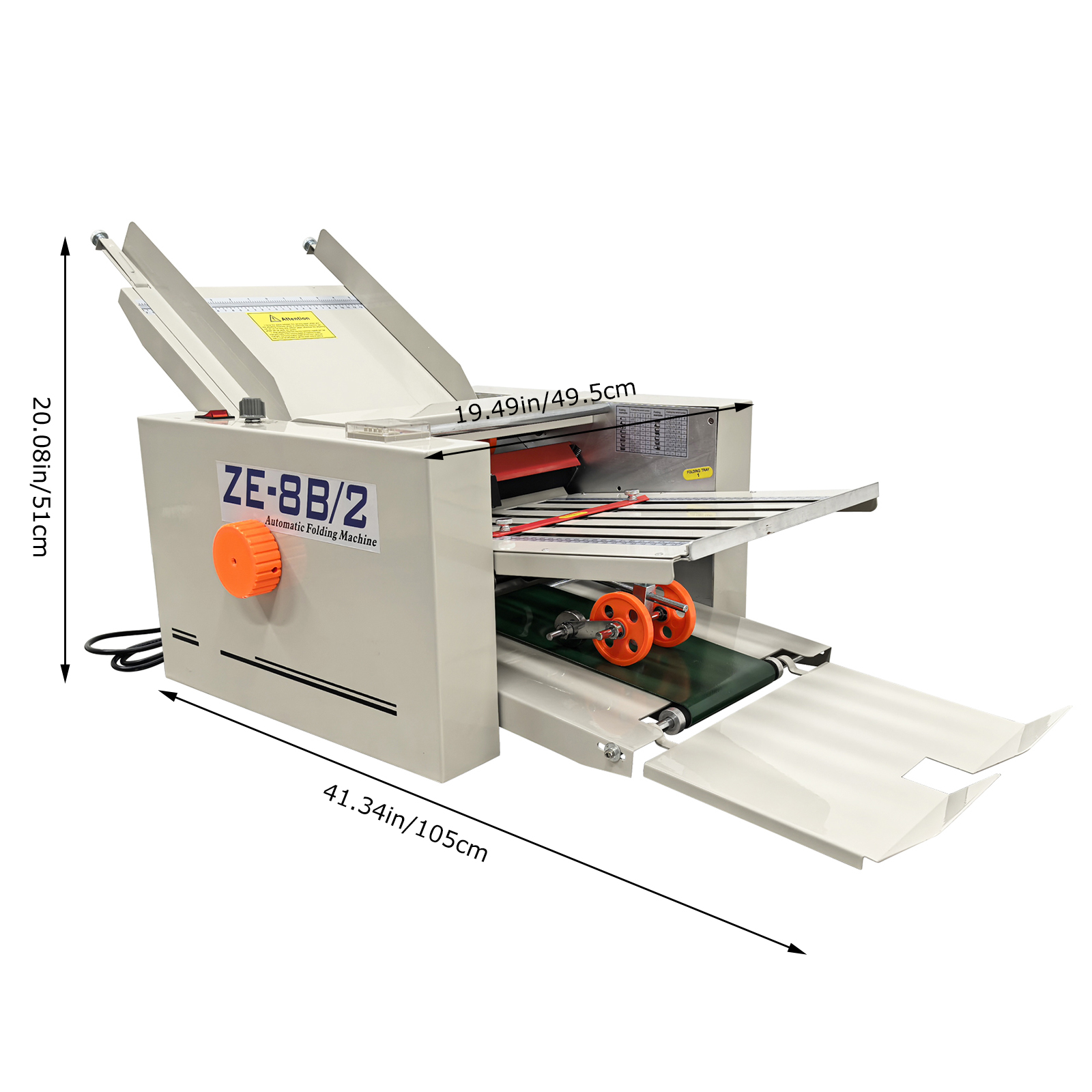

Machine size |

105*49.5*51cm (41.34*19.49*20.08 inches) |

|

Net weight |

34.7kg (76.5LB) |

|

|

|

|

Attention |

|

1. Please ensure the good grounding

connection before using the machine. |

|

2. Keep hands, clothing and tools away

from moving parts while the machine is in operation. |

|

3. Do not put hands into the machine

during operation. |

|

4. Be sure to disconnect the power supply

before repairing and maintaining the machine. |

|

Product

Features |

|

|

|

|

|

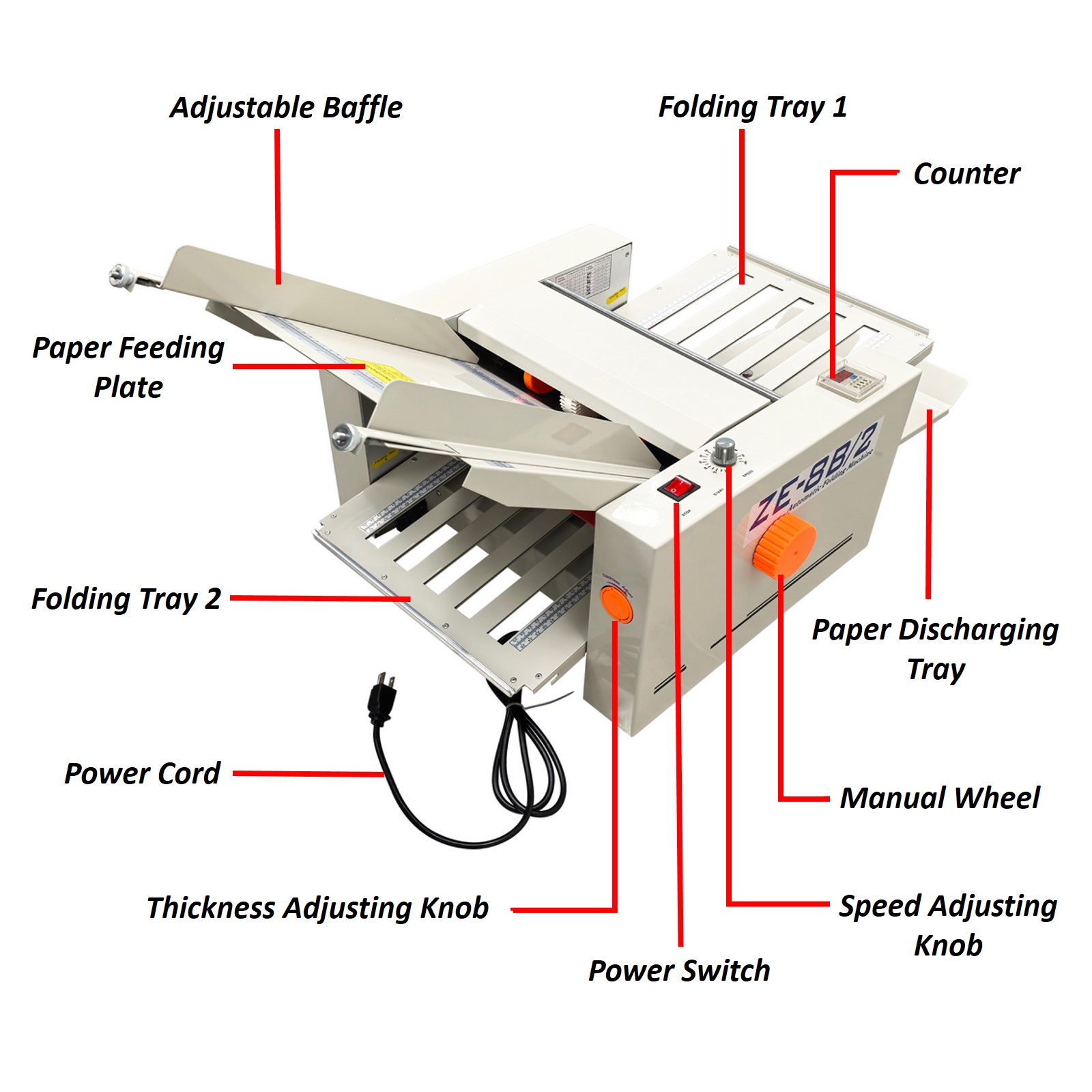

Smooth

feeding and dimension adjustability. The firm paper feeding

plate is detachably designed for the machine, and the paper

baffles on the two sides can be easily adjusted to limit the

size of paper to be folded so that the paper can be smoothly fed

into the machine, the phenomenon that a pad of paper is fed

manually one by one can be avoided, and the time and labor are

saved.

Note: It is suggested that before feeding, you can twist the

paper to form a slope so as to facilitate paper feeding. |

|

Automatic paper

separation. The white paper separating wheel cooperates with the

green wheel to achieve effective paper separation. After the

paper is fed, the paper can be separated one by one to

facilitate folding operation in the next procedure, so that the

degree of automation is high. The gap between the white paper

separating wheel and the green wheel can be adjusted to adapt

different paper thicknesses, and the automatic paper separating

effect can be well achieved.

|

|

|

|

|

|

Automatic counting.

The folding machine is equipped with a counter which can count

the number of folded paper sheets automatically. You can set the

number of sheets you want to fold by pressing the key. For

example, when you put 20 sheets of paper on the machine, but you

only want to fold 10 sheets, you can set the number "0010" on

the control panel, and the machine will stop automatically after

folding 10 sheets.

Note: When you want to continue folding

paper in the later period, be sure to adjust the number of this

counter. When "0000" is displayed, the paper cannot be folded.

|

|

Speed

adjustability. The speed adjusting knob is designed on one side

of the folding machine and can be easily rotated to adjust the

folding speed. The folding speed can be controlled accurately to

adapt to various kinds of paper with different dimensions and

thicknesses, so that the folding flexibility is well enhanced.

By the use of the speed adjusting knob, the actual production

demand can be well met, the balance of the speed and performance

can be achieved, and the production benefit can be maximized. |

|

|

|

|

|

|

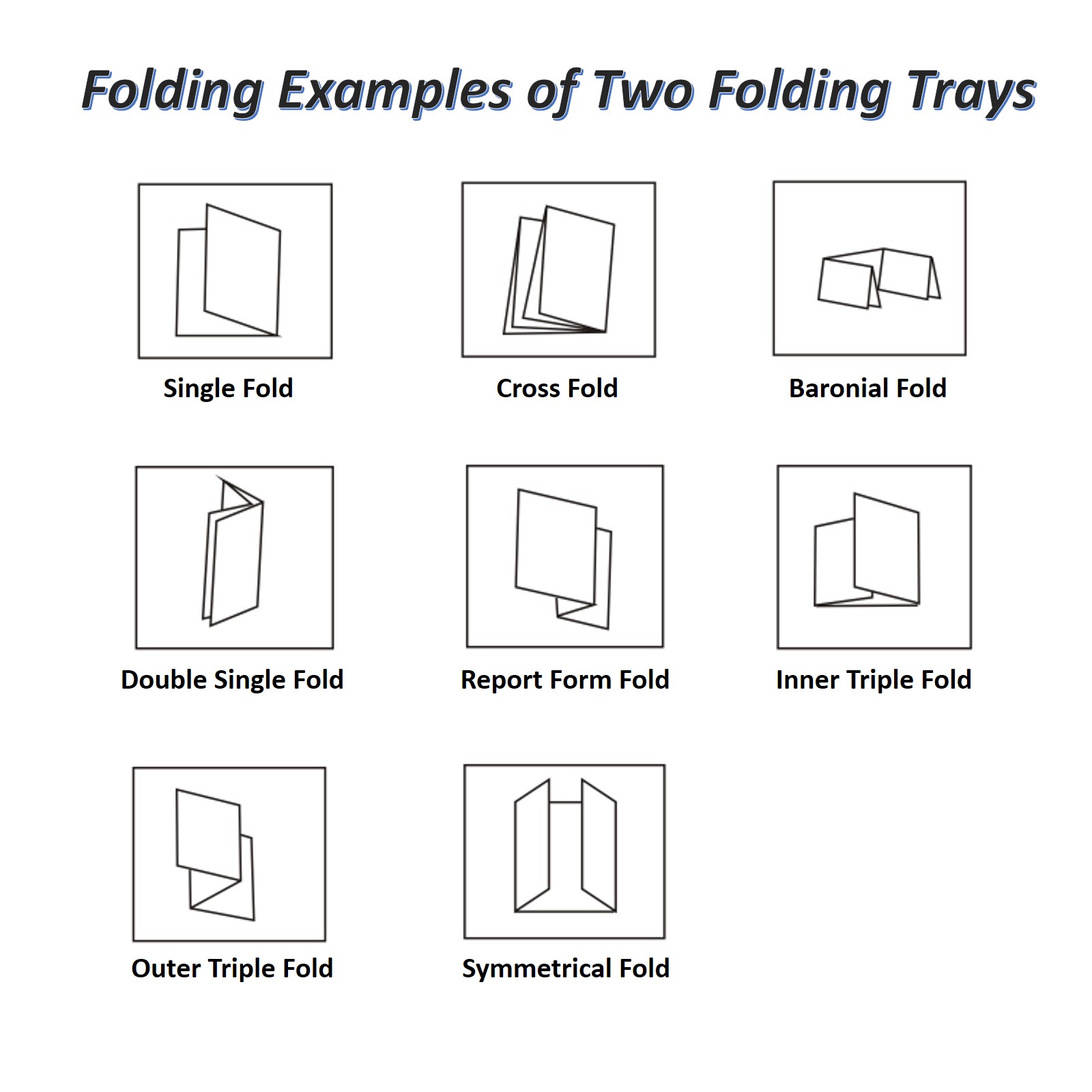

Effective and precise folding. The automatic paper folding

machine is equipped with 2 folding trays with scales. The two

folding trays can be used independently or cooperatively to

achieve different folding styles. When each folding tray is not

used, the operator can rotate it by 180 degrees to install it in

place. The red transverse rod on each folding tray can be

adjusted according to the actual folding size to meet different

folding requirements, so that the adjustment is easy and

accurate. |

|

Effective thickness

adjustment. The thickness adjuster is designed for adjusting the

gap between the white paper separating wheel and the green wheel

to form the appropriate friction so as to separate paper and

feed paper one by one. The knob can be rotated in the direction

of the arrow to enlarge or reduce the gap, adjustment is easy

and convenient, and the adaptability is well ensured. |

|

|

|

|

|

|

Convenient indenting adjustment. The two indenting wheels are

adopted to form the indentations of different folded products.

When you want to form a cross fold, the horizontal crease is

folded by adjusting the first folding tray, and the vertical

crease is the indentation. The operator can adjust the position

of the two indenting wheels at the arrow. When the two wheels

are closer to the middle, the vertical indentation becomes

deeper. When the two wheels are farther away from the middle,

the vertical indentation disappears. |

|

Appropriate

pressing and smooth discharge. After the paper is folded, the

finished products can be pressed by the paper pressing wheels

appropriately and be smoothly discharged from the machine, so

that the pressing effect is good, and the folding effect is well

kept. The paper pressing wheels can be disassembled when the

machine is adjusted, assembling and disassembling are easy and

convenient, the operating difficulty is greatly reduced, and the

user experience is well enhanced. |

|

|

Operation

Method |

|

1. Open the package, check whether all

accessories are available and assemble and adjust all the accessories on

the machine. |

|

2. Connect the power plug of the machine to

the 110V power socket with grounding connection. |

|

3. Twist the paper sheets to form a slope

and place them on the paper feeding plate. |

|

4. Adjust the speed knob to set the

appropriate speed, turn on the power switch, and the machine will fold

the paper sheets automatically. |

|

5. After finishing the folding operation,

turn off the power switch and unplug the machine. |

|

Application |

|

As a professional folding device, the

automatic paper folding machine can fold various paper sheets with

different sizes and thicknesses and can be widely used in the printing

industry, the packaging industry, the logistics industry, the

manufacturing industry, the educational industry, the service industry

and so on. It is an optimum choice for customers. |

|

|

Product

Display |

|

|

|

|

|

Item Number (122131): 1 x

Automatic Paper Folding Machine 110V |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |