|

|

|

|

Terminal Crimping Machine Cable Wire Stripping and Crimping Machine 220V

1PH |

|

|

|

|

|

|

|

|

Product

Overview |

|

The

automatic wire stripping and terminal crimping machine is a

professional device for wire harness processing, adopts the

advanced electronic control technology and is equipped with a

high-precision control module and transmission mechanism,

enabling the wire stripping and terminal crimping to be

completed in one go. It has the advantages of low noise, low

power consumption, high efficiency and so on. The machine has a

significant processing effect on the extremely fine wires and

multi-core shielded wires and is suitable for AWG30-AWG20

terminal crimping.

The

wire stripping action of the machine is driven by an air

cylinder, the wire stripping speed is high, and positioning is

accurate. The waste material generated after wire stripping is

sucked in a vacuum mode, which is clean, convenient and simple.

The pressing machine is driven by gear reduction, and the

pressure is highly precise. For inexperienced and experienced

operators, the overall speed of the machine can be changed by

adjusting the air valve, thereby adapting to the proficiency

level of the operators. |

|

|

Product

Parameters |

|

Whole machine |

|

Power supply |

220V 1PH

(Note: A 110V

transformer is given as a present. If your power supply is 110V,

you can connect the machine to the transformer and then connect

the transformer to your 110V power supply.) |

|

Air source |

0.3~0.4Mpa

(Please use dry and clean air.) |

|

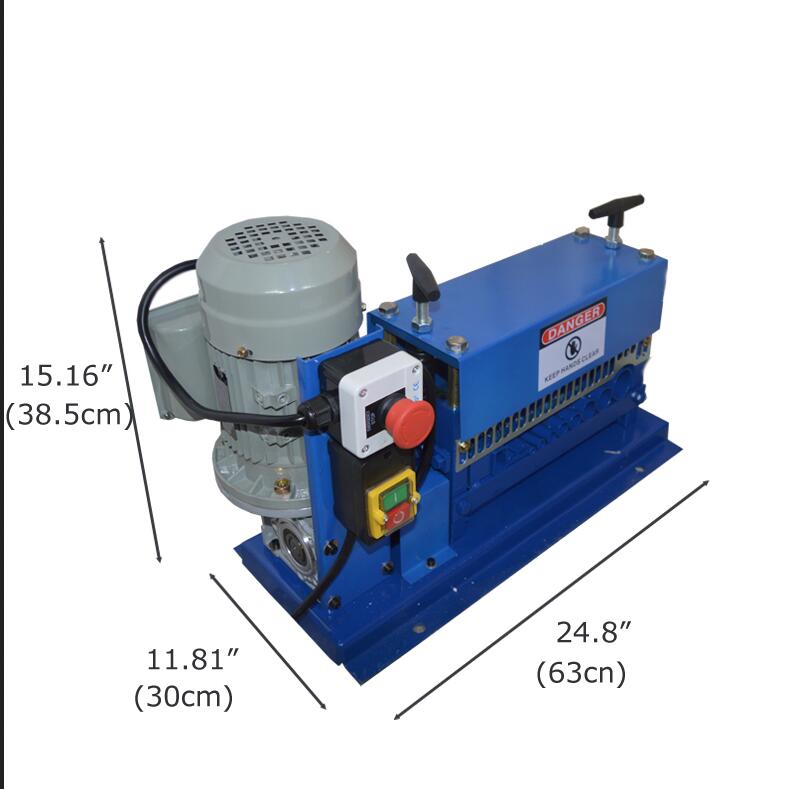

Product size |

63x41x89cm (24.8x16.1x35 inches) |

|

Net weight |

67kg (147.7LBS) |

|

Wires to be processed |

|

Applicable wire diameter |

AWG30-AWG20 (depending on the wires) |

|

Applicable wires |

AV, AVS, AVSS, CAVUS, KV, KIV, UL, IV PTFE, fiber

wires, etc. |

|

Processing size |

|

Wire stripping length |

1.0mm-10.0mm |

|

Wire cutting error |

0.05mm-0.1mm |

|

Position error |

0.05mm-0.1mm |

|

Crimping force |

|

Crimped terminal |

Open continuous terminal, horizontal |

|

Terminal model |

XH2.5 (The separation distance is 2.5mm.) |

|

Crimping capacity |

1.5T |

|

Travel |

30mm |

|

Power |

400W |

|

Number of strokes |

4000 times/hour |

|

Opening height |

215mm |

|

|

|

Attention |

|

1.

Operation notes

1.1. Before crimping the terminals, ensure that

when the air pressure is connected to the ventilation switch,

the stripping structure is kept at the starting working

position.

1.2. Before crimping of the terminals, both the

motor switch and the stripping switch need to be turned on.

1.2.1. When the motor switch is not turned on,

the motor does not work and there is only the wire stripping

motion.

1.2.2. When the stripping switch is not turned

on, there is only the terminal crimping motion. When only the

terminal needs to be pressed, the total air pressure must be

closed.

1.3. Before crimping of the terminals, the

sliding block must be stopped at the topmost state.

2.

Maintenance and upkeep

2.1. Clean the machine every day, remove any

remaining wire sheaths and other things, and keep the machine

clean.

2.2. Pour the lubricating oil into the machine

sliding block and wire cutting slide group every week.

2.3. Drain the air filter every day.

2.4. Regularly check the looseness of machine

components and screws, and promptly tighten them. |

|

|

Product

Features |

|

|

|

|

|

|

1.

The control panel is simple and compact in structure, different

functions can be fulfilled through the corresponding buttons, the

response speed is high, and the machine operation and adjustment are

flexible and convenient.

2.

The high-quality motor is used for providing the stable driving force

for the wire stripping and terminal crimping motions, and has the

advantages of low energy consumption, low noise and stable performance.

3.

The high-precision clamping type mold is adopted to facilitate

replacement, and the terminals can be more attractive. The mold is

subjected to quenching, electroplating and other technologies, the

service life is obviously prolonged. The wire stripping depth can be

adjusted as needed, and the high terminal crimping precision and speed

are achieved.

4.

Feeding and waste collection are automatically conducted at the same

time, the working efficiency is greatly improved, and the workbench is

kept clean and orderly.

5.

The high-quality pressure gauge is adopted to accurately detect and

clearly display the air pressure, achieving real-time monitoring and

detection and ensuring that the air pressure can be more stable.

6.

The LED lighting lamp is designed for illumination during operation. It

can be independently controlled to be turned on and off, the energy

consumption is low, the light is soft and is not dazzling, and the angle

can be freely adjusted to adapt to different working environments.

7.

The paper collector switch will be triggered when the material strip is

fed to a certain extent, automatic paper collection is facilitated, and

the sensor has high sensitivity and can assist in feeding.

8.

The power transformer can effectively transform 110V power to 220 power,

ensuring the 220V machine can be normally used in the environment with

the 110V power. The transformer is high in quality and practicability.

|

|

Operation

Method |

|

1. Operation panel |

|

|

● Counter: Record the processing

quantity and output.

● Clear key: Set the number of the counter to zero, and start

counting from zero.

● Up and Down keys: Adjust the sliding block to move up and down

in the manual state to facilitate adjustment of the height of

the blade.

● SET key: Used for internal frequency modulation, and already

set at the factory.

● Automatic/Manual key: The switch for alternating the machine

adjustment and automatic cycle operation.

● Cut key: In the machine adjustment process, the motions of

cutting the wire sheath and fixing the wire clamp can be

completed separately.

● Strip key: It can be used to retract when the wire sheath is

stripped separately in the machine adjustment process.

● Trial key: In the machine adjustment process, the wire

stripping motion can be conducted separately.

● Total power supply: Main power switch.

● Motor switch: The motor motion can be started and stopped.

● Stripping switch: It can start and stop the stripping motion.

When only the terminal needs to be pressed, the total air

pressure must be closed. When the motor switch and stripping

switch are turned on at the same time, wire stripping and

terminal crimping can be automatically conducted by stepping on

the foot pedal.

● Lighting button: Lighting lamp switch.

|

|

|

2.

Function adjustment

●

Terminal mold adjustment: Take out the mold, adjust the

positions of the terminal and the cutter base to align the rear

pin of the terminal with the cutter core edge, and then adjust

the feeding length.

●

Pressure adjustment: Turn the manual and automatic key indicator

light to the red state, press the up and down keys directly, and

repeat adjusting the pressure height until the desired

requirement is met. When the machine is adjusted, the total air

pressure switch must be turned off. After the punch stroke is

halfway, press the manual and automatic key, and the indicator

light will be green. Step on the foot pedal, and the punch can

automatically reset (return to the origin).

●

Wire cutting length adjustment: Adjust the screw, tighten the

nut after the screw is in place, and test the cut key.

●

Wire cutting depth adjustment: Adjust the screw, tighten the nut

after the screw is in place, and test the cut key.

●

Adjustment of wire fixing clamp: Adjust the positioning screw,

tighten the nut after the screw is in place, and test the cut

key.

●

Adjustment of the wire cutting position and the front and back

position of the terminal: Loosen the positioning screw, directly

adjust it to the correct position, then tighten the screw, and

manually press the terminal for testing.

●

Press the trial key to conduct trial stripping of the wire

sheath.

●

Press the automatic/manual key, the indicator light will be

green, and step on the foot pedal to conduct automatic wire

stripping and terminal crimping. |

|

|

Product

Display |

|

|

|

|

|

Item Number (057231): 1 x Cable Wire

Stripping and Crimping Machine 220V |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|