|

|

新建网页 2

|

110V Digital Drawer Exposure Unit |

Product Overview:

The drawer-type small exposure unit is a

precision device used in screen printing, pad printing, and other

printing processes for plate exposure and plate-making. Its core

function is to cure the photosensitive material on the printing plate

through ultraviolet (UV) light, forming the graphic plate required for

printing. With a compact design, it is suitable for small printing

workshops or studios.

|

Core Functions and

Applications:

Function Positioning: Through ultraviolet

exposure, the photosensitive layer on the printing plate (such as PS

plate, resin plate, pad printing steel plate, etc.) is cured, achieving

graphic "development" and providing accurate printing materials for

subsequent printing.

Applicable scenarios: It is widely used in

processes such as screen printing (e.gscreen plate making in

advertising, textiles, electronics, etc.) and pad printing

(e.g.small-area printing on glass, ceramics, plastics, etc.), serving as

a key equipment in the pre-press plate-making stage. |

|

Structure and Technical

Features:

Drawer-Type Design:

It adopts a drawer-type operating mechanism,

offering convenient operation for easily placing/removing printing

plates and improving work efficiency.

Some models are equipped with a vacuum adsorption system to ensure tight

contact between the printing plate and the light source device,

preventing graphic distortion caused by "air

bubbles" during exposure and guaranteeing exposure accuracy.

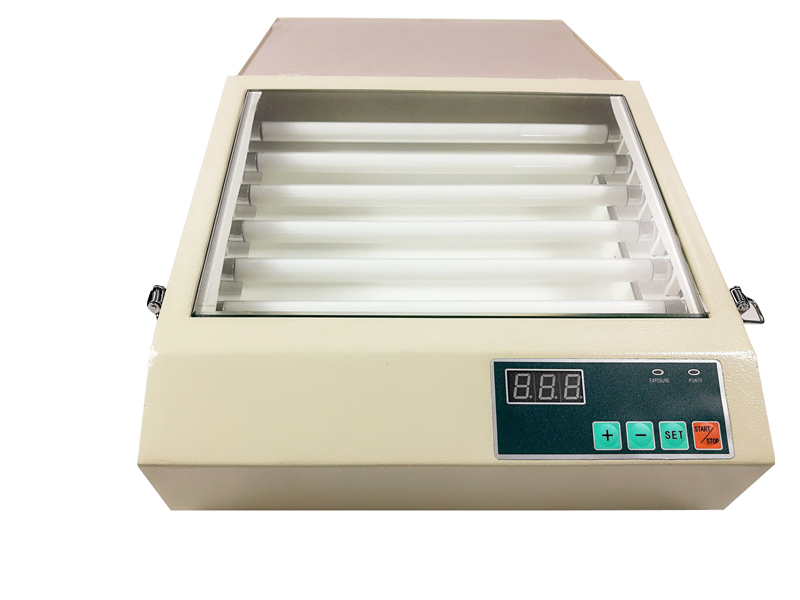

Light Source and Control:

Equipped with 6 UV lamps, the multi-tube

layout optimizes illumination uniformity and reduces exposure

unevenness.

Equipped with a digital control panel (as shown by the buttons and

display screen in the image), it allows precise setting of exposure

time, light source intensity, and other parameters, supports

manual/automatic mode switching, and meets the exposure requirements of

different printing processes.

|

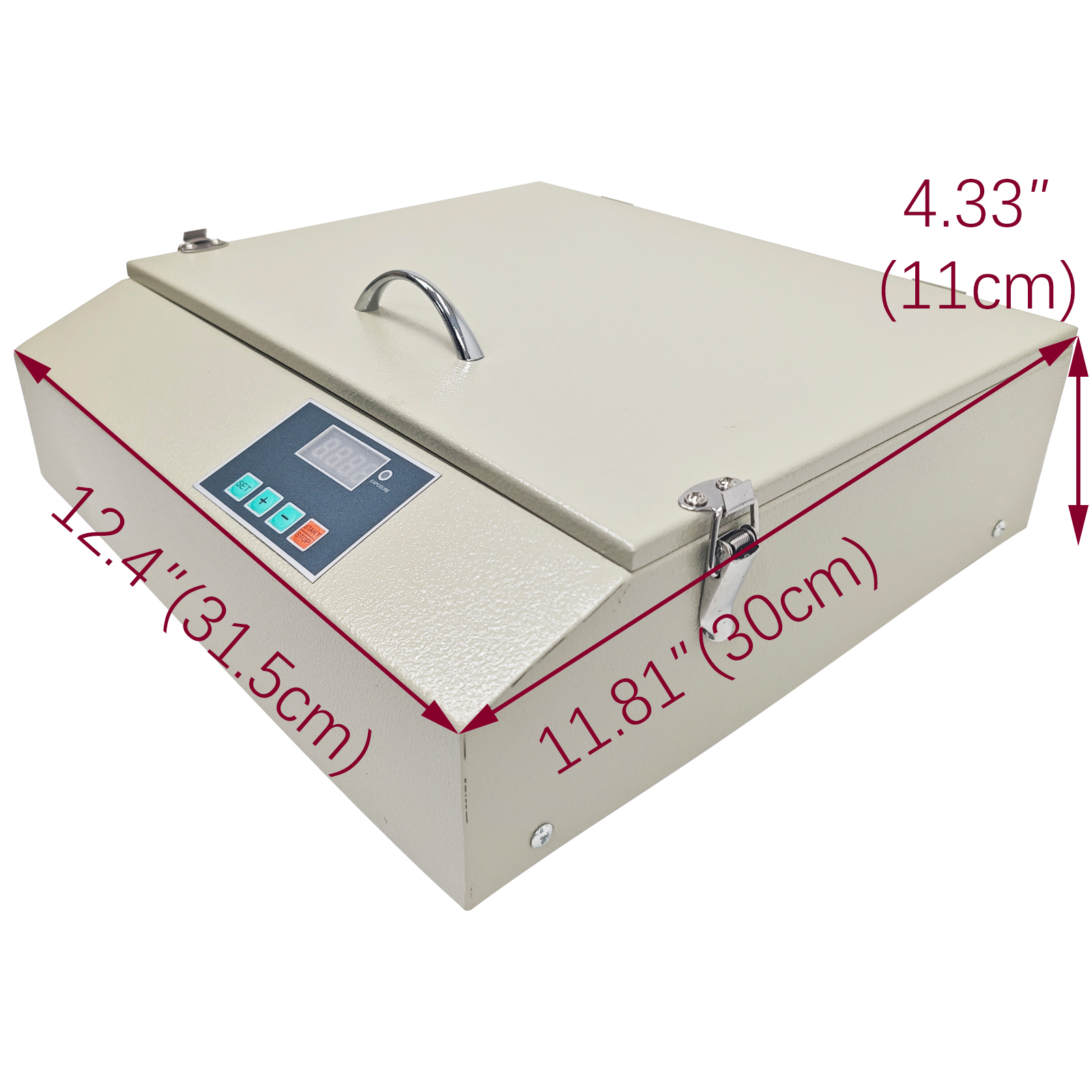

Technical Parameters

:

Maximum Exposure Area: Approx. 11.02×8.27″ (28*21cm)

Power Supply & Power Consumption: 110V, Approx. 48W (8W per lamp tube)

Dimensions: 11.81*12.4*4.33″ (30*31.5*11cm) |

|

|

Industry

Applications and Advantages:

Industry Coverage: Widely used in advertising printing, textile

printing, electronic component printing, pad printing

(glass/ceramics/plastics, etc.), serving as a core equipment in the

pre-press plate-making process.

Core Advantages:

High illumination uniformity ensures the clarity of the plate image and

graphics;

Stable light intensity/wavelength prevents exposure parameter

fluctuations from affecting print quality;

Vacuum suction design (on select models) enhances contact between the

plate material and light source, reducing the rejection rate;

The compact design adapts to studios, small factories, and similar

scenarios, reducing the spatial footprint while lowering overall costs.

|

|

Other Details: |

|

High-quality drawer handle for convenient

operation.

One-touch buckle: Press the buckle to lock the machine instantly,

eliminating the need for additional tools or complex steps,

significantly lowering the operational threshold and improving work

efficiency.

|

|

Two types of screens will

be shipped randomly. |

|

|

Item Number: 110V Digital

Drawer Exposure Unit - 010034 |

|

You can make

order with no worries.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|